10月15日,全球塑料与橡胶工业盛会K2025 圆满落幕。海天国际以“Level Up!Your Advantage–全面跃升·由此发生”为主题,聚焦包装、医疗、汽车、光学四大行业,从生产力、灵活度、效率、生态四大维度,为全球客户呈现了一场智造盛宴,不仅收获全球客户的广泛认可,更让“全面跃升”从主题变为可感知的产业价值。

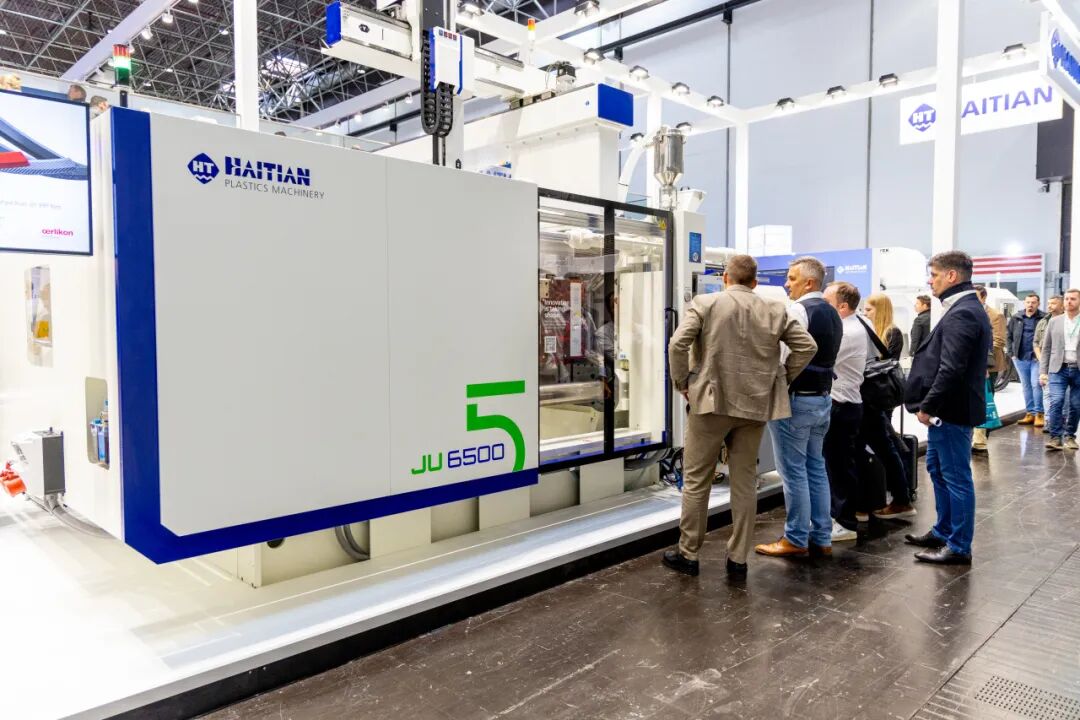

首秀的长飞亚 ZEV-F 全电动包装机,搭配灵智保等智能技术,集成海天智联的IML包装自动化单元,实现全年稳定连续生产,展示智能一体化的高速包装解决方案;长飞亚ZE系列医疗专机严格遵循GMP 洁净标准,全流程安全可追溯,筑牢医疗制品安全精度底线;同样首秀的海天MAV/FPRO 伺服液压高速机,呈现薄壁包装方案,优化能耗管理,平衡高效生产与节能;海天JU系列二板机依托IMD 一体成型工艺,直接生产汽车A级可视件,兼顾外观与精度,契合可持续制造趋势;首次登陆K展的日本新泻 Niigata 全电动立式注塑机,展示光学嵌件应用的新方案,为高精度成型打开更多可能。

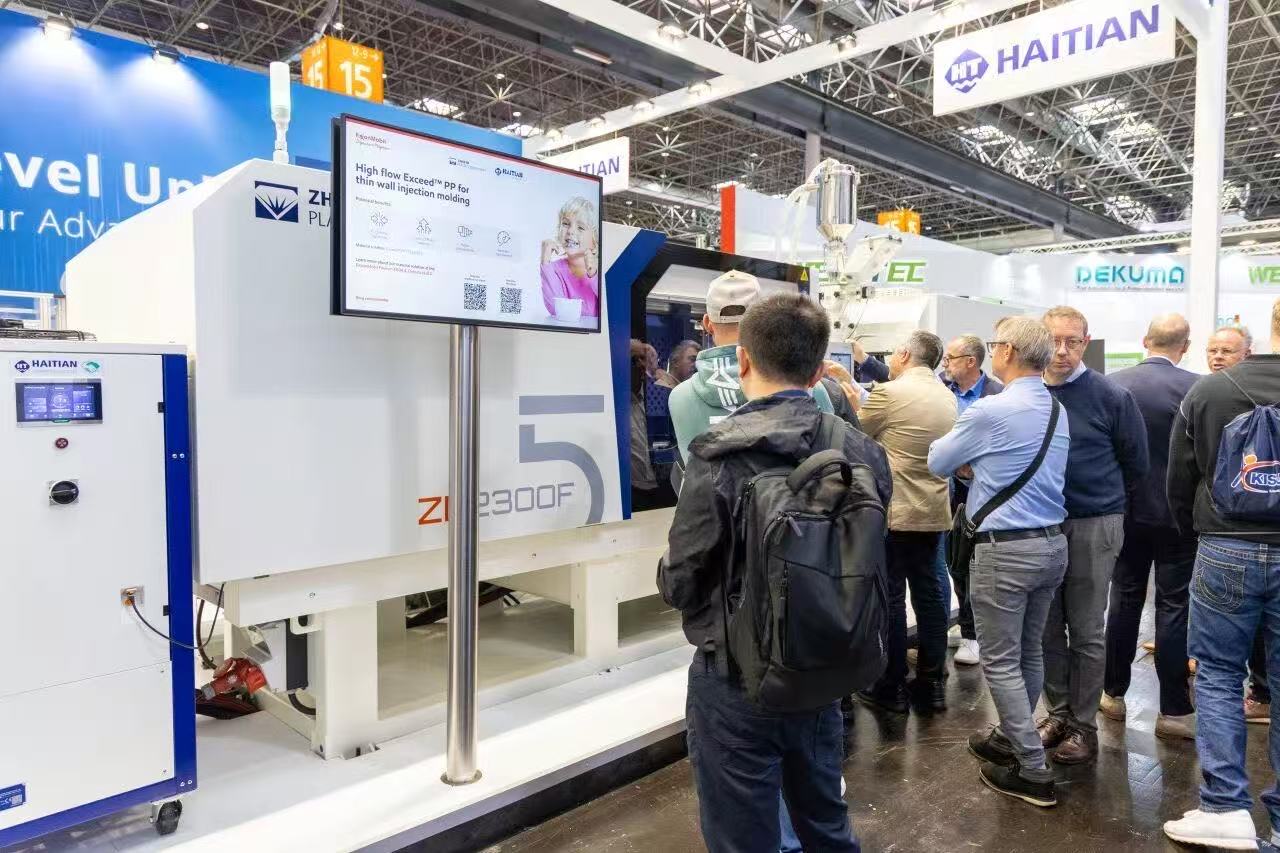

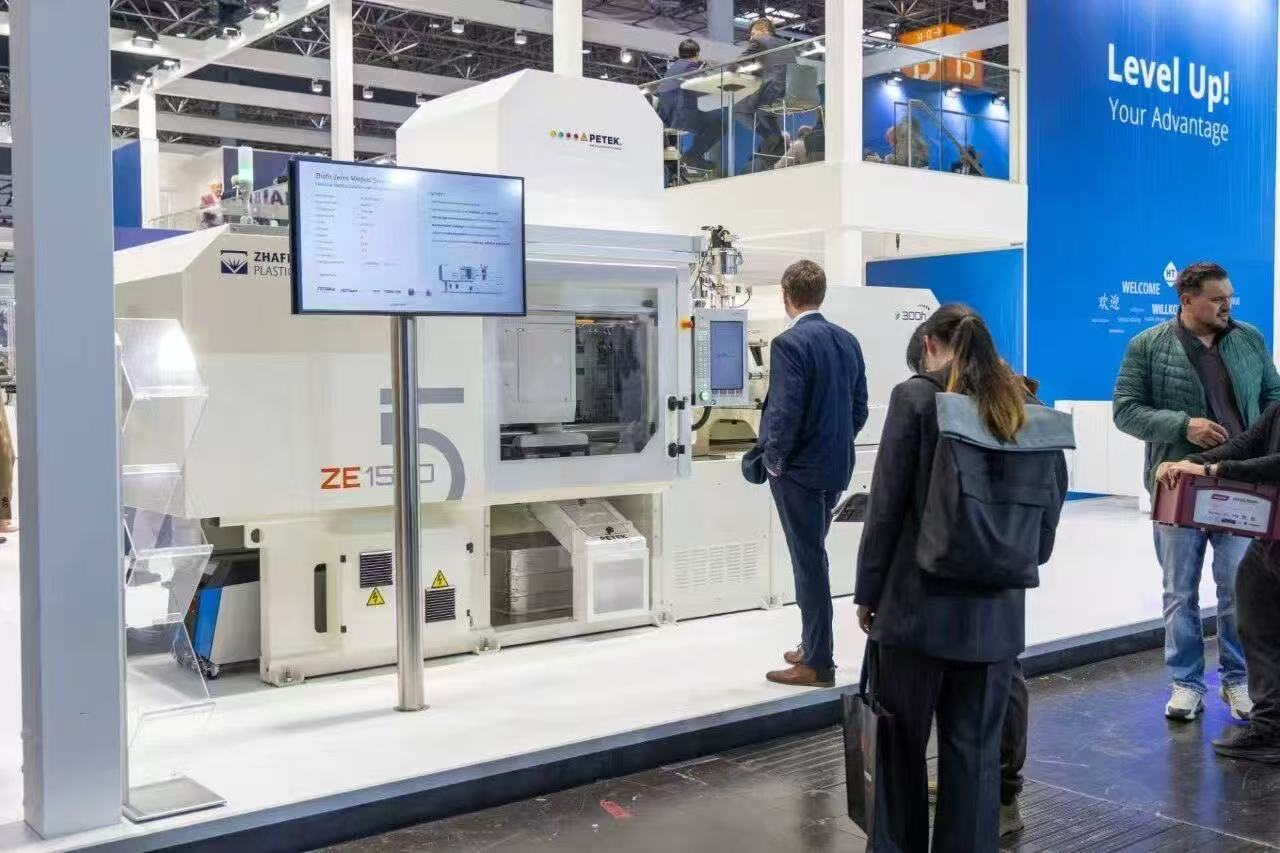

连日来,展台前汇聚了来自全球各地的客户与合作伙伴,现场观众围绕这些机型方案深度交流,对海天国际呈现的生产力解决方案表示高度认可。

灵活度跃升

以开放集成平台,打破产线壁垒

针对全球客户多样化的产线布局需求,海天国际在本次展会里呈现“开放式集成”核心优势,消除设备协同中的品牌与技术壁垒:

所有海天与长飞飞亚机型均配备标准Euromap接口用户可自由选择并集成任意品牌的外围设备与自动化系统。并通过海天智联的系统整合能力,机器人、辅机与生产单元可灵活组合、按需扩展,为客户提供真正的个性化智能生产方案。海天国际致力于打造开放式集成平台,实现注塑机与周边设备的灵活衔接,构建自由互联的智能生态。

效率升级

低成本迈入数字化智造

同时,首次亮相的“X注塑云”AI智能工艺助手,也成为展出亮点。它覆盖从工艺开发到量产优化全流程,助力客户实现智造升维。

生态升级

注塑+,延伸智能制造边界